Fabricación de espumas de SiC de bajo costo a partir de azúcar y plantillas poliméricas recicladas

Fabrication of low-cost SiC foams from sugar and recycled polymeric templates

Contenido principal del artículo

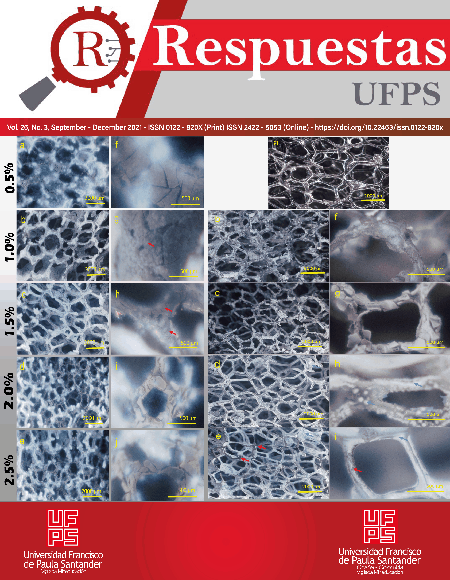

Las espumas cerámicas macroporosas son utilizadas en diferentes campos debido a sus propiedades únicas, que incluyen: baja densidad, baja conductividad térmica, alta permeabilidad, estabilidad a altas temperaturas y alta resistencia al ataque químico. Las espumas de carburo de silicio (SiC) altamente porosas son materiales de gran interés en diferentes aplicaciones industriales como absorción, soportes catalíticos, aislamiento térmico, entre otros, debido a su inercia química, gran área superficial, baja resistencia al flujo, baja caída de presión, así como alta resistencia a la temperatura y a la corrosión. En este trabajo, se fabricaron espumas de SiC altamente porosas mediante una técnica de réplica en plantilla, utilizando espumas poliméricas recicladas como plantillas de sacrificio. Como precursor, se usó una resina a base de sacarosa con contenido de sílice en polvo. Las plantillas poliméricas se impregnaron, seguido de tratamiento térmico a 1500 °C bajo atmósfera inerte. El efecto de la relación de masa C/SiO2 (1.0-1.75) en el precursor y el uso de alúmina (0.5 - 2.5 % p/v) como aditivo de sinterización se evaluaron en términos de la morfología de las espumas resultantes, así como del rendimiento de SiC.

Descargas

Detalles del artículo

S. T. Gopi, S. and A. Pius, “Synthesis, microstructure, and properties of high-strength,” in Fundamental Biomaterials: Ceramics, 2018, p. 265.

J. Luyten, S. Mullens, J. Cooymans, A. M. De Wilde, I. Thijs, and R. Kemps, “Different methods to synthesize ceramic foams,” J. Eur. Ceram. Soc., vol. 29, no. 5, pp. 829–832, 2009.

J. H. Eom, Y. W. Kim, and S. Raju, “Processing and properties of macroporous silicon carbide ceramics: A review,” J. Asian Ceram. Soc., vol. 1, no. 3, pp. 220–242, 2013.

A. Gómez-Gómez, J. J. Moyano, B. Román-Manso, M. Belmonte, P. Miranzo, and M. I. Osendi, “Highly-porous hierarchical SiC structures obtained by filament printing and partial sintering,” J. Eur. Ceram. Soc., vol. 39, no. 4, pp. 688–695, 2019.

G. Jean, V. Sciamanna, M. Demuynck, F. Cambier, and M. Gonon, “Macroporous ceramics: Novel route using partial sintering of alumina-powder agglomerates obtained by spray-drying,” Ceram. Int., vol. 40, no. 7 PART A, pp. 10197–10203, 2014.

S. Hooshmand, J. Nordin, and F. Akhtar, “Porous alumina ceramics by gel casting: Effect of type of sacrificial template on the properties,” Int. J. Ceram. Eng. Sci., vol. 1, no. 2, pp. 77–84, 2019.

N. Hedayat, Y. Du, and H. Ilkhani, “Review on fabrication techniques for porous electrodes of solid oxide fuel cells by sacrificial template methods,” Renew. Sustain. Energy Rev., vol. 77, no. April, pp. 1221–1239, 2017.

D. C. Jana, G. Sundararajan, and K. Chattopadhyay, “Effect of Porosity on Structure, Young’s Modulus, and Thermal Conductivity of SiC Foams by Direct Foaming and Gelcasting,” J. Am. Ceram. Soc., vol. 100, no. 1, pp. 312–322, 2017.

Z. Du et al., “The high porosity silicon nitride foams prepared by the direct foaming method,” Ceram. Int., vol. 45, no. 2, pp. 2124–2130, 2019.

I. H. Song, J. H. Ha, M. J. Park, H. D. Kim, and Y. W. Kim, “Effects of silicon particle size on microstructure and permeability of silicon-bonded SiC ceramics,” J. Ceram. Soc. Japan, vol. 120, no. 1405, pp. 370–374, 2012.

T. Kovářík et al., “Synthesis of open-cell ceramic foam derived from geopolymer precursor via replica technique,” Mater. Lett., vol. 209, pp. 497–500, 2017.

P. Krawiec and S. Kaskel, “Thermal stability of high surface area silicon carbide materials,” J. Solid State Chem., vol. 179, no. 8, pp. 2281–2289, 2006.

T. Fey, U. Betke, S. Rannabauer, and M. Scheffler, “Reticulated Replica Ceramic Foams: Processing, Functionalization, and Characterization,” Adv. Eng. Mater., vol. 19, no. 10, pp. 1–15, 2017.

C. Duong-Viet et al., “Silicon carbide foam as a porous support platform for catalytic applications,” New J. Chem., vol. 40, no. 5, pp. 4285–4299, 2016.

C. Durif et al., “Open-celled silicon carbide foams with high porosity from boron-modified polycarbosilanes,” J. Eur. Ceram. Soc., vol. 39, no. 16, pp. 5114–5122, 2019.

Y. W. Kim, J. H. Eom, C. Wang, and C. B. Park, “Processing of porous silicon carbide ceramics from carbon-filled polysiloxane by extrusion and carbothermal reduction,” J. Am. Ceram. Soc., vol. 91, no. 4, pp. 1361–1364, 2008.

R. Mouazer, S. Mullens, I. Thijs, J. Luvten, and A. Buekenhoudt, “Silicon carbide foams by polyurethane replica technique,” Adv. Eng. Mater., vol. 7, no. 12, pp. 1124–1128, 2005.

M. R. Nangrejo and M. J. Edirisinghe, “Porosity and strength of silicon carbide foams prepared using preceramic polymers,” J. Porous Mater., vol. 9, no. 2, pp. 131–140, 2002.

C. Vix-Guterl and P. Ehrburger, “Effect of the properties of a carbon substrate on its reaction with silica for silicon carbide formation,” Carbon N. Y., vol. 35, no. 10–11, pp. 1587–1592, 1997.

D. H. Filsinger and D. B. Bourrie, “Silica to Silicon: Key Carbothermic Reactions and Kinetics,” J. Am. Ceram. Soc., vol. 73, no. 6, pp. 1726–1732, 1990.

N. Shcherban et al., “Morphological features of porous silicon carbide obtained via a carbothermal method,” Int. J. Appl. Ceram. Technol., vol. 15, no. 1, pp. 36–41, 2018.

J. Qian, J. Wang, and Z. Jin, “Preparation of biomorphic SiC ceramic by carbothermal reduction of oak wood charcoal,” Mater. Sci. Eng. A, vol. 371, no. 1–2, pp. 229–235, 2004.

W. R. Schmidt, R. H. Doremus, L. V. Interrante, T. K. Trout, P. S. Marchetti, and G. E. Maciel, “Pyrolysis Chemistry of an Organometallic Precursor to Silicon Carbide,” Chem. Mater., vol. 3, no. 2, pp. 257–267, 1991.

A. Giachello, P. C. Martinengo, G. Tommasini, and P. Popper, “Sintering of silicon nitride in a powder bed,” J. Mater. Sci., vol. 14, no. 12, pp. 2825–2830, 1979.

K. Negita, “Effective Sintering Aids for Silicon Carbide Ceramics: Reactivities of Silicon Carbide with Various Additives,” J. Am. Ceram. Soc., vol. 69, no. 12, p. C‐308-C‐310, 1986.

K. Negita, “Effective Sintering Aids for Silicon Carbide Ceramics: Reactivities of Silicon Carbide with Various Additives,” J. Am. Ceram. Soc., vol. 69, no. 12, p. C‐308-C‐310, 1986.

Perfil Google Scholar

Perfil Google Scholar